Few techniques are as versatile and essential as die cutting when it comes to custom packaging. From intricate box shapes to precise cutouts for branding, die cutting plays a crucial role in creating packaging that’s not just functional but eye-catching and memorable.

If you’ve ever wondered what “die cut” points in the packaging world or how the process works, you’re in the right place. In this post, we’ll break down everything you need to know about die cutting, its purpose in custom packaging, and how D Custom Boxes uses it to promote brand representation.

What is Die Cutting?

At its core, die cutting is a fabrication method that applies cutting, shaping, or perforating materials like envelopes, cardboard, or folded stock using a specially developed tool named a die.

Think of it like a big cookie edge. Just as a cookie knife cuts out a distinct shape from dough, a die cuts a shape out of packaging fabric. This process allows for precise, consistent cuts perfect for crafting business packaging components such as box windows, folding tabs, business strategies, or branding cutouts.

What Does “Die Cut” Mean?

The term “die cut” directs to anything that holds been cut using a die. In packaging, a “die cut box” generally signifies a box that has been manufactured with business cuts and forms, created to fold a certain way or feature unique design parts.

Examples include:

- Custom-shaped boxes (e.g., hexagonal, pillow, display boxes)

- Packaging windows to showcase products

- Slots or handles for ease of use

- Brand logos are cut directly into the surface

- Tuck flaps and locking mechanisms are cut for the structure

In short, die cutting allows packaging to be tailored to the brand, product, and user experience.

The Die Cut Process – Step by Step

Let’s break down how the die-cut process works, especially as it applies to box manufacturing:

1. Design Creation

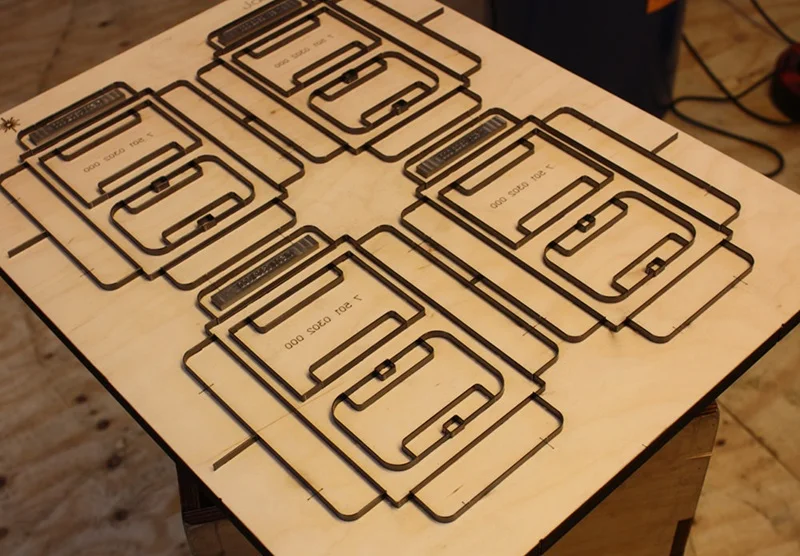

First, a structural design is made using specialized software. This method acts as the blueprint for the package, including sizes, folds, and cut bars.

2. Die Fabrication

A custom die is made, usually out of steel blades mounted on a wooden base. This tool matches the exact layout of the design. Some dies are flat, others are rotary (for large runs), depending on the machinery and job size.

3. Material Preparation

The selected material—cardstock, corrugated board, kraft paper, etc.—is loaded into the cutting machine.

4. Die Cutting

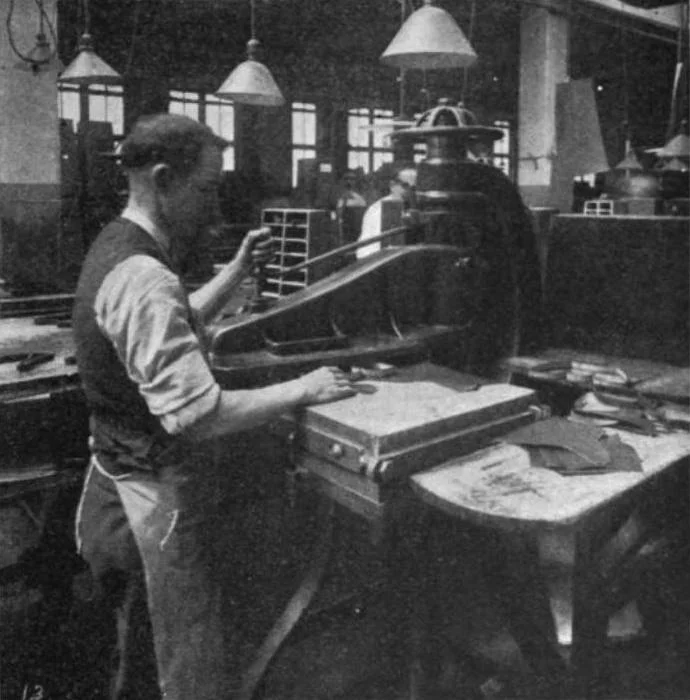

The die is pushed into the textile to cut the design. This can be accomplished manually, with a hydraulic press, or with automatic machinery for larger show runs.

5. Creasing & Scoring

To help the packaging fold perfectly, crease lines are counted where curves or folds will appear. This provides a clean, skilled finish and prevents cracking.

6. Stripping

After the body is cut, excess material is released from the die-cut sheet, a process understood as stripping. What remains is your dead die-cut layout, prepared for folding or gluing.

7. Finishing

The die-cut boxes can then be created, published, laminated, embossed, or further customized established on the brand’s requirements.

Types of Die Cutting Used in Packaging

There are several kinds of die-cutting techniques, and the choice depends on the complexity and quantity of the packaging needed:

1. Flatbed Die Cutting

Best for short runs and intricate designs. It offers high precision and flexibility for custom jobs.

2. Rotary Die Cutting

Used for high-volume production. A cylindrical die rotates over the material to continuously cut shapes in a fast and consistent manner.

3. Digital Die Cutting

No physical die is required—machines use lasers or blades to cut directly from a digital file. Ideal for prototypes or limited editions.

Why Die Cutting Matters in Custom Packaging

At D Custom Boxes, we leverage die cutting because it allows for:

- Fully custom designs that stand out on shelves

- Unique box styles that fit your product perfectly

- Functional features (like handles, inserts, and windows)

- Consistent results, no matter the size of the order

- Cost-effective production for bulk runs

In today’s competitive retail and eCommerce markets, standard box shapes just won’t cut it anymore—pun intended. A well-executed die-cut design can make the difference between a customer tossing your box aside or snapping a photo to share it online.

Common Die-Cut Box Styles

Here are some famous types of die-cut packages we offer at D Custom Boxes:

- Tuck-End Boxes: Easy to assemble, ideal for cosmetics, accessories, and retail entities.

- Mailer Boxes: Great for subscription boxes and online stores. Sturdy, modern, and perfect for branding.

- Window Boxes: Feature a die-cut window to showcase the product without emptying the container.

- Display Boxes: Created for countertops or frames, combining packaging with point-of-sale functionality.

- Pillow Boxes: A stylish option for little items like jewelry or acceptance.

Die Cutting vs. Regular Cutting: What’s the Distinction?

While both methods involve trimming, die cutting is highly detailed and repetitive, ideal for large batches or intricate forms. Regular cutting (like guillotining) is straight-line, simple, and manual, better suited for trimming or sizing.

Die cutting also allows:

- Better accuracy

- Repeated designs with zero deviation

- Creative and artistic customizations

- Faster production in scale

Why Choose D Custom Boxes for Die-Cut Packaging?

At D Custom Boxes, we specialize in fully customizable packaging using accurate die-cutting processes customized to your brand. Here’s what sets us separated:

- Free structural design & die-line support

- Affordable die charges (often waived for large orders)

- Low minimum order quantities

- Eco-friendly and recyclable materials

- Fast turnaround & global shipping

Whether you’re launching a new development, refreshing your packaging, or making influencer boxes, our professional team can help you create packaging that not only covers your product but even boosts your brand in a big way.

Final Thoughts

In the world of custom packaging, die cutting is the tool that transforms a simple box into an experience. It’s the key to turning your packaging from functional to unforgettable.

From precise cuts and branded windows to box styles that fit your product perfectly, die cutting is an essential process for companies that want to stand out.

D Custom Boxes combines state-of-the-art die-cutting techniques with years of industry expertise to deliver packaging that performs as beautifully as it looks.

Ready to create your custom die-cut packaging? Contact us today for a free quote and design consultation—your next best-selling box starts here.