At D Custom Boxes, we’ve seen it all: boxes that were too big, packages that got returned, and shipments that cost double because of measurement mistakes. You wouldn’t think how many individuals guess their box dimensions and cross their fingers. Here’s the fact: if you know how to calculate your box perfectly, you’ll avoid headaches, save money, and ensure your load or storage job is done exemplarily.

This guide is a no-nonsense walkthrough for anyone who likes to get the size of a box right, whether you’re sending something necessary, ordering packaging for your business, or just trying to organize your garage.

Why Proper Box Measurement Matters

Think about this: You buy a custom box, only to find out your product doesn’t fit — or you ship something light, but in a big box, and get slammed with extra charges because of dimensional weight.

That’s where D Custom Boxes comes in. We help customers like you avoid those costly mistakes every single day. And it all starts with knowing how to measure your box correctly.

What You’ll Need

Before you begin, grab these essential means:

- A measuring video(preferably soft and flexible, but a traditional ruler functions too)

- A pen and something to document on (or just use your phone’s notes app)

- The actual container, fully assembled and closed

That’s it! You don’t need fancy equipment. Just a little attention to detail.

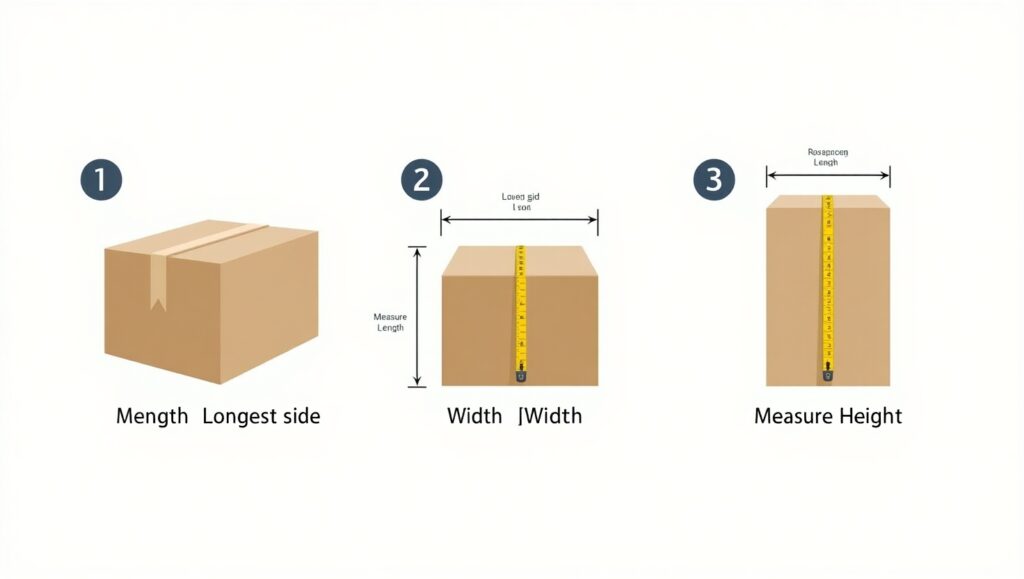

The Three Key Dimensions: Length, Width, Height

No matter the shape or size, every box has three main measurements. Always list them in this order:

- Length – the longest side of the base

- Width – the shorter side of the base

- Height (sometimes called depth) – from the bottom to the top when the box is upright

Pro Tip from D Custom Boxes: Think of a pizza box. When it’s sitting or lying on your aircraft, the size is left-to-right, the width is front-to-back, and the height is how elevated the box stands.

Step-by-Step: How to Measure a Box

Let’s walk through it like we’re right there with you.

1. Measure the Length

Place the box on a flat surface. The longest side on the bottom is your length. Use the tape measure from edge to edge.

Write it down.

Example: 14 inches

2. Measure the Width

Still working from the bottom of the box, measure the shorter side — that’s the width.

Add it to your list.

Example: 9 inches

3. Measure the Height

Now, measure from the bottom of the box to the very top — that’s your height. If the box has flaps, keep them closed while measuring.

Record it.

Example: 6 inches

So for this box, your full dimensions would be written as:

14 x 9 x 6 inches

This is the industry standard, and it’s what we use at D Custom Boxes when making your custom packaging.

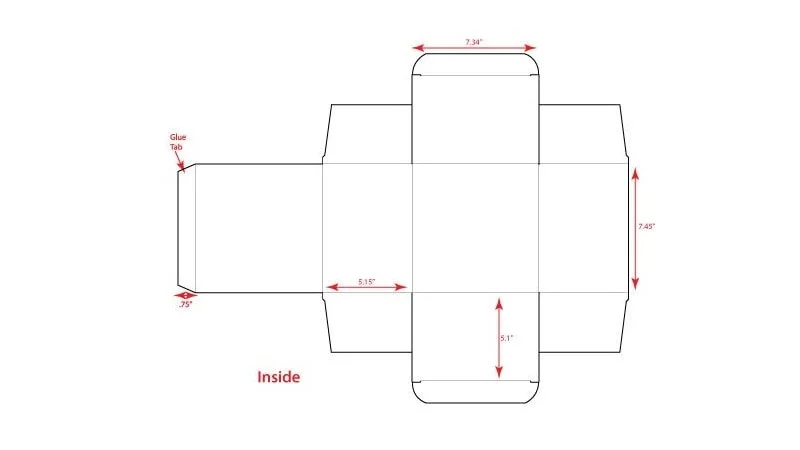

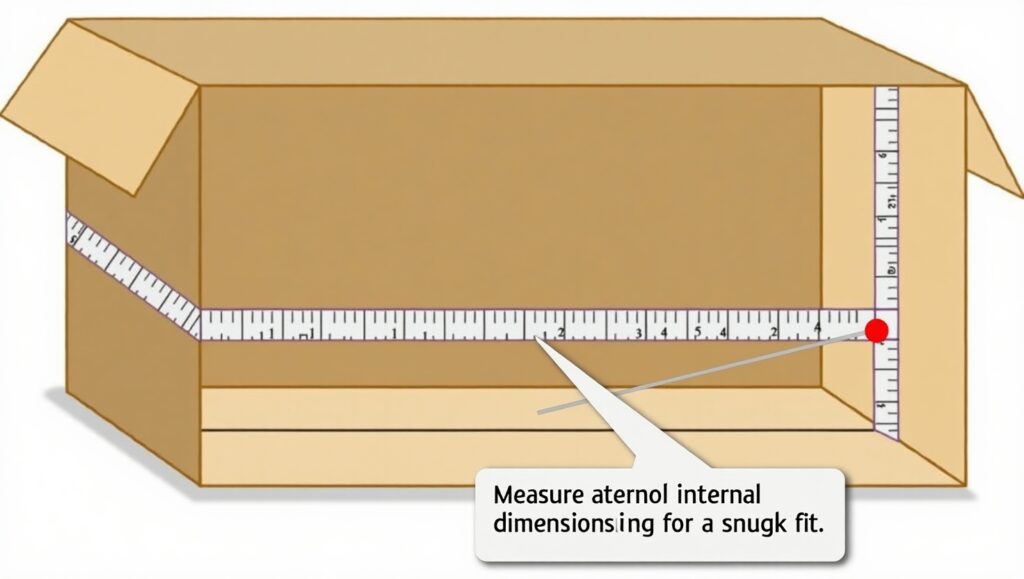

Measuring the Inside of the Box (When Fit Actually Matters)

If you’re packing a development inside the box and it ought to fit snugly, you’ll need the interior measurements:

- Open the box completely.

- Measure from inside wall to inside wall — not the outer edges.

- If the box is thick (like double-wall cardboard), subtract a bit to account for the material.

At D Custom Boxes, we often ask clients for inside dimensions when designing inserts or precise fit packaging.

Shipping Boxes: Why Accurate Measurements Save You Money

Most carriers — like USPS, FedEx, or UPS — don’t just care about weight. They are set up based on dimensional weight, particularly for larger parcels that don’t fit well.

That’s why it’s important to count accurately and round up to the nearest inch.

Here’s the calculation:

Length × Width × Height = Volume (in cubic inches)

Example:

14 x 9 x 6 = 756 cubic inches

Shipping companies then use a procedure to estimate what they’ll trust you. That’s why it’s worth double-checking your dimensions—every inch totals.

D Custom Boxes Tip: If you’re creating boxes for e-commerce or bulk shipping, talk to us first. We can help you design sizes that minimize shipping costs without sacrificing presentation.

Advanced Tips from D Custom Boxes

If you’re a small company owner, a craftsperson, or just somebody who cares about facts, these suggestions can help:

- Use a digital caliper if you’re operating with tiny or delicate creations.

- Double-check your units. Mixing up hairs and centimeters is additional typical than you think, particularly with global orders.

- Measure twice, cut once. Even with boxes, this age-old advice applies.

FAQ: You Asked, We Answered

Q: Do the flaps count in the height?

A: If you’re measuring a box as it will be shipped, yes. Measure it fully closed.

Q: Is it always length x width x height?

A: Yes. That’s the universal order, and it’s what we follow at D Custom Boxes.

Q: What if my box isn’t a perfect shape?

A: Measure the widest points. For oddly shaped boxes or cylinders, you’ll want the diameter and height.

Q: I’m shipping delicate things, should I leave room for padding?

A: Absolutely. If your development is 10 inches long, choose a box that’s 12–13 inches long to leave room for foam or bubble wrap.

Want to Calculate Volume?

Here’s the basic volume formula:

Volume = Length × Width × Height

If you want to convert it:

- To cubic feet: divide by 1,728

- To cubic centimeters: use cm instead of inches

Example:

14 x 9 x 6 = 756 cubic inches

756 ÷ 1,728 = 0.44 cubic feet

This helps when you’re figuring out warehouse space, storage bins, or even how many boxes fit in a truck.

Final Thoughts from D Custom Boxes

We know — it’s just a box. But getting the dimensions right? That’s what makes the difference between an okay experience and a smooth, professional one.

At D Custom Boxes, we believe packaging isn’t just about looks. It’s a close fit, process, and it makes your life more comfortable. Whether you’re sending effects to clients or managing your house, learning how to estimate your box properly is the first step toward bringing it directly.

So next time you’ve got a tape measure in hand, remember:

Length × Width × Height.

Write it down. Double-check. You’ll thank yourself later.

Need help choosing the right size box or want to design something custom? Reach out to us at D Custom Boxes — we’re real people who care about getting your packaging just right.